Roller granulator uses dry granulation technology. You need to place raw materials for production in a boot port, And the two -vale extrusion granulator will miss your raw materials through two rollers for extrusion granular. The final product will be released from below.

Roller granulator

- The size of the particles: 2 -10 mm

- The degree of granulation: 98% +

- Production capacity: 1 – 4 subject.

- The size of the particles of raw materials before granulation: 10 oven.

- Moisture content of raw materials before granulation: 2% – 6%

- Equipment material: Carbon steel Q235 + 20CRMNTI or 4CR13

- Application: Powder compost, Phosphorus fertilizers, potassium fertilizers, Ammonium sulfate, Technical salt, NPK, Mineral fertilizers…

The design of our roller granulator is very reasonable, What not only facilitates your work, but also provides continuous production for you. Compared to other granulators, Two -wool granulator not only reduces energy consumption, but also provides the degree of granulation 98%. Pellets, produced by a two -wound extrusion granulator, They have low humidity, convenient in storage and do not require equipment with additional drying equipment, which allows you to reduce your production costs.

How much does the roller granulator of our plant cost? - - the price of the roller granulator for the model.

We know, that the cost of investment in granular equipment is crucial for your solution. Therefore, we pay special attention to the provision of roller granulators with excellent characteristics and affordable price. Will help you achieve effective production activities and investment payback. Choosing our equipment, You not only get a high -quality roller granulator, but also get complex support of products and maintenance.

Below are the prices for our roller granulators:

SXDG – 1T —— 1600 US dollars.

Two -wrench granulator with performance 1 ton/time: The price is indicated 1600 US dollars. This model is suitable for small business and beginner fertilizers manufacturers. The possibility of achieving stable production with smaller investments.

SXDG – 1,5T —— 1800 US dollars.

Roller granulator with performance 1,5 tons/time: price 1800 US dollars. Suitable for enterprises with a growing business. This device provides a good balance between price and performance.

SXDG – 2T —— 2000 US dollars.

Roller granulator with performance 2 T/hour: price 2000 US dollars. For customers, which requires a large production capacity, This equipment can satisfy higher production needs.

Prices on Different models of roller granulation equipment are different. You can inform us of the expected production volumes, Requirements for the size of particles and requirements for pressing rolls. Based on these data, we will provide a model and the number of two -wound extrusion granulator, which meets your requirements. And provide the most reasonable proposal. No matter, Are you a small business or a major manufacturer. We can provide you with the most suitable solution for roller granulation, which will help you succeed.

Two roller granulators with various unloading modes are available to your choice. Increase the effectiveness of your production line!

For that, To satisfy various projects for laying lines for the production of customer fertilizers. We reformed and modernized the roller granulator. Two roller granulators with various unloading modes have been developed: Front and lateral. They are suitable for use in various production situations. No matter, Are you a small business or a major manufacturer, You can buy and use it.

Roller granulator s frontal unloading:

The roller granulator with frontal unloading can unload materials directly from the front. It has a simple structure and convenient management. Contributes to daily inspection and maintenance. By optimizing the unloading route, it is possible to reduce the time of particle stay in the granulation zone. This reduces potential damage to materials, temperature or pressure.

Roller granulator s side unloading:

The roller granulator with side unloading unloads the material on the side. This design reduces the total length of the device. Especially suitable for enterprises, which needs to achieve compact placement of production. Will help you save a valuable production space and simplify the connection of equipment. It is very suitable for production lines with limited space or special processes.

When choosing a roller granulator, corresponding to your needs, It is necessary to take into account many aspects. This includes not only technological requirements, premises layout and ease of equipment maintenance. Such factors are also taken into account, as characteristics of raw materials, Production efficiency, Cost and safety. If you have questions about that, Which granulator is suitable for your production line, Contact us to get professional consultation.

How many tons of high -quality ready -made granules per hour we can produce for you on our two -vale granulator?

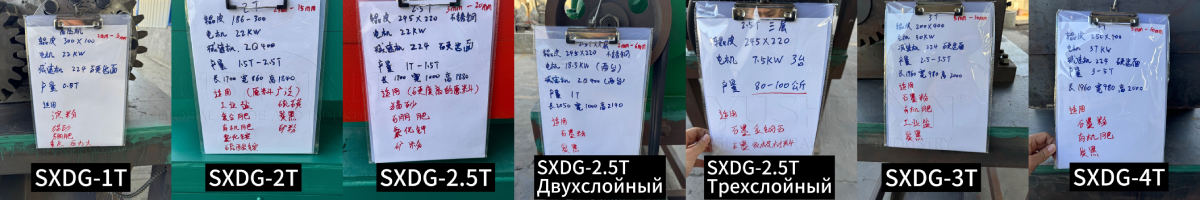

Different types of two -wound extrusion granulators have different performance per hour. Currently The main models of two -wound extrusion granulators, produced by our company, are: SXDG-1T, SXDG-1.5T, SXDG-2T, SXDG-2T-Ⅱ, SXDG-2.5T, SXDG-2.5T-ⅱ, SXDG-3T and SXDG-4T. The actual volume of production will depend on many factors. Including the size of the products, Characteristics of raw materials, Settings of equipment parameters, Maintenance, Operator skills, Environmental conditions, preliminary processing of raw materials and formula development and t. e.

Take as an example SXDG-1T. Pellet production 4 mm is 0,6-0,7 Tons, and pellet production in size 5 mm - 1,1-1,2 Tons. Particle output size 6 mm can achieve 1,5-1,7 Tons, and the output of particles in size 8 mm can achieve 1,7-1,8 Tons. The larger the particles, The higher the output.

The corresponding characteristics of raw materials and the exact settings of the parameters of the process can increase the efficiency of granulation. Regular maintenance of equipment provides stable operation of the machine. Besides, The reasonable process of pre -processing and the development of the recipe are crucial. Effectively controlling these factors and optimizing them, You can significantly increase the performance and quality of the granules of your roll granulator.

| Type | Total power (kW) | The diameter of the particles (mm) | The size of the skin of the roller (mm) | Dimensional dimensions (mm) | Performance range (subject) |

|---|---|---|---|---|---|

| SXDG-1T | 11 | 2-10 | Φ151*220 | 1430*750*1350 | 0.8-1.5 |

| SXDG-1.5T | 18,5 | 2-10 | Φ151*300 | 1560*800*1580 | 1-2 |

| SXDG-2T | 22 | 2-10 | Φ186*300 | 1560*800*1580 | 1.5-2.5 |

| SXDG-2T-Ⅱ | 15*2 | 2-10 | Φ186*300 | 2170*1000*1850 | 1.2-1.5 |

| SXDG-2.5T | 22 | 2-10 | Φ245*220 | 1700*1000*1670 | 1-1.5 |

| SXDG-2.5T-ⅱ | 18,5*2 | 2-10 | Φ242*220 | 2170*1000*1850 | 1.3-1.8 |

| SXDG-3T | 30 | 2-10 | Φ200*400 | 1960*980*1760 | 2.5-3.5 |

| SXDG-4T | 37 | 2-10 | Φ250*400 | 1960*980*1760 | 3-5 |

In which areas you can use a roller granulator to produce granules?

As a granulator of dry granulation. Particles, which he produces, No need to dry and cool. Because of its characteristics, it is more popular among manufacturers, which needs to make granules. Because it can save production processes and costs. Areas of application are wide and are not limited to a fertilizer area. Generally speaking, areas with a large number of applications:

In the pharmaceutical industry, roller granulators are used to produce medicines granules, to ensure the exact dosage of the drug and the convenience of carrying and taking.

It can be used to produce animal feed granules, such as cattle and bird, as well as to improve taste and nutritional value of feed due to the processing of raw materials.

In the food industry, roller granulators can be used to produce food granules of a certain shape and taste. For example, flakes, snacks and t. e.

And in the mining industry, you can use a two -year granulator to process ore and other raw materials into granules. To facilitate subsequent processing and transportation.

What raw materials can you granulate using a roller granulator?

Two -wool granulator – This is a type of equipment, usually used to granate powdered materials. It is widely used in the production of organic fertilizers, complex fertilizers, chemical industry, fertilizers, Medicine, food and other industries. Below are some common raw materials, which can be granulated using a roller granulator:

So, how large granules can make our roller granulator for you?

Our two -wool extrusion granulator can produce granules for you with a diameter from 3 to 10 mm. Adjust the distance between the two rollers in accordance with your requirements for the size of the particles. Thus, Producing the size of the product, which you want.

Certainly, If you also have the requirements for the form of particles, We can configure ballpoints on the roller shell in accordance with your requirements. Whether it is a flat spherical, semicircular, in the form of a pillow or tablet. All, What do you want, We can configure.

What is the size of your raw materials, so that our roller granulator can be used for granulation?

Our two -wound extrusion granulator can granulate raw materials in size 50-200 oven, that is 0,27-0,074 mm. If the size of your raw materials for fertilizers is within this range, You can safely use our two -wool granulator. If the size of your raw materials for fertilizers is not in this range, We recommend you Equip a grinder. Raw materials are crushed to a suitable size, and then granulated using a two -wool granulator.

What to do, If your raw material causes corrosion?

The videos of each of our roller granulators are made of 20CRMO. 20CRMO is a low alloy steel. It has good strength and shock viscosity and is widely used in the production of mechanical parts, requiring high strength and wear resistance. The main alloying elements of steel are 20hrom. 0,17-0,24 % carbon (With), 0,40-0,70 % manganese (Mn), 0,90-1,20 % Chrome (Cr) And 0,15-0,25 % Molibden (We). We apply an anti -corrosion coating to the surface of the clips of steel 20crmo, to increase their corrosion resistance. So you have nothing to worry about.

Two ways to adjust the pressure of the rollers of the two -wool granulator.

In the work of the two -wound granulator, the adjustment of the roller pressure is a key step. This allows you to produce granules of fertilizers of perfect density. So how to adjust the pressure of the rollers? A two -wool granulator at our factory can be adjusted in the following methods. Select a suitable adjustment method, Based on specific production requirements and equipment configuration. Allows you to achieve the best production results.

How to extend the service life of your two -vale extrusion granulator?

First, What should be noted, This is what, that your raw materials cannot contain iron. The hardness of the iron is very high, It is easy to damage the roller shaft in your roller extrusion granulator. Before starting a two -wound granulator, it is necessary to spread the oil on its gears, To lubricate the gears. Besides, You also need to check, whether the two -wool granulator contains materials before starting. It is forbidden to open a two -year extrusion granulator along with the material.

Every three days you need to lubricate the chain and stars, To reduce wear. After use, it is necessary to clean the material inside the roller granulator and apply oil to Grinding roller, to prevent his rust and corrosion.

If you want to know more about the methods of servicing a two -wool extrusion granulator, You can contact us.

In addition to a biabler granulator, You can choose some other equipment for the production of high -quality granular fertilizers?

If you need it, We can build a suitable for you Double roller production line.

If you want to make finished granular fertilizer more beautiful and popular, You can Equip the ruggish and roller extrusion granulator together.

If you want to increase production efficiency, You can equip a car and use it with a roller extrusion granulator. Sifting car can separate the finished granular fertilizer from the powder. The separated material can also be re -granulated. Reduce material losses.

If you need it, We can build a suitable for you Double roller production line.

If you want to make finished granular fertilizer more beautiful and popular, You can Equip the ruggish and roller extrusion granulator together.

If you want to increase production efficiency, You can equip a car and use it with a roller extrusion granulator. Sifting car can separate the finished granular fertilizer from the powder. The separated material can also be re -granulated. Reduce material losses.

How often will you get our two -wool granulator?

If you purchased a two -year extrusion granulator is available, We will deliver it to you on the same day. If not in a warehouse. We will produce and deliver you the two -wool extrusion granulator you bought during 15 days.

Why choose us as a manufacturer of two -wound extrusion granulators?

- Rich experience and knowledge: We have many years of experience and knowledge in the industry. For more than twenty years, we have been developing and producing high -performance two -wool extrusion granulators. Ensure the provision of advanced decisions to clients

- High -quality products: Our granulator uses high -quality materials and advanced production processes. Ensure the durability and stability of equipment to satisfy various production needs.

- Individual solutions: We provide individual services for the design and production of equipment, taking into account the specific needs of customers. Ensure maximum functionality and effectiveness of your equipment.

- Ideal after -sales service: We provide comprehensive after -sales support. Including installation guide, Operation and maintenance services training and services. Make sure, that your equipment is always in perfect condition.

- High cost efficiency: We strive to provide customers with high efficiency products. Let you get high -quality equipment at a reasonable price.

If you are interested in our roller extrusion granulator, Contact us.