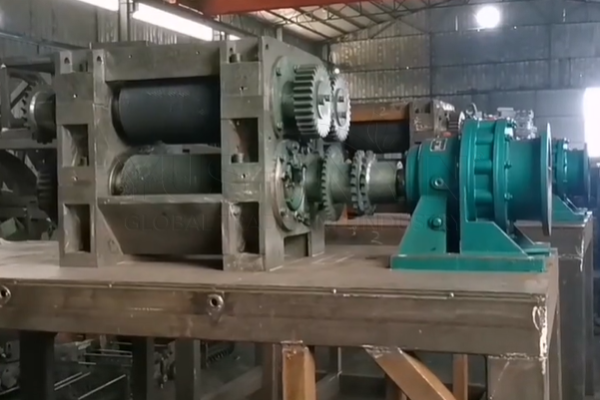

Two-layer two-rope granulator SXDG-2.5T-Professional equipment, designed for pressing powder materials in granules. Widely used in chemical, chemical, pharmaceutical and food industry. Thanks to the accurately designed two -layer rolling of rolls, this equipment can effectively increase the density and quality of particles.

Two -layer roller granulator

- Model: SXDG-2.5T

- The size of the particles: 2 -10 mm

- The degree of granulation: 98% +

- Production capacity: 1 – 1,5 subject.

- The size of the particles of raw materials before granulation: 10 oven.

- Moisture content of raw materials before granulation: 2% – 6%

- Application: Powder compost, Phosphorus fertilizers, potassium fertilizers, Ammonium sulfate, Technical salt, NPK, Mineral fertilizers, graphite powder, Technical carbon…

The principle of operation is a two -layer roller granulator.

Unlike Two -wound granulator, The core of this granulator SXDG-2.5T is a two-layer roll. The videos rotate synchronously by means of chain and gear transmission. After that, how the material enters the equipment through the loading hole, It is first pressed by the first layer of rollers. Then further pressing occurs on the second layer of rollers. After two -layer pressing, the material is pressed into particles of a homogeneous form and unloaded through the outlet hole.

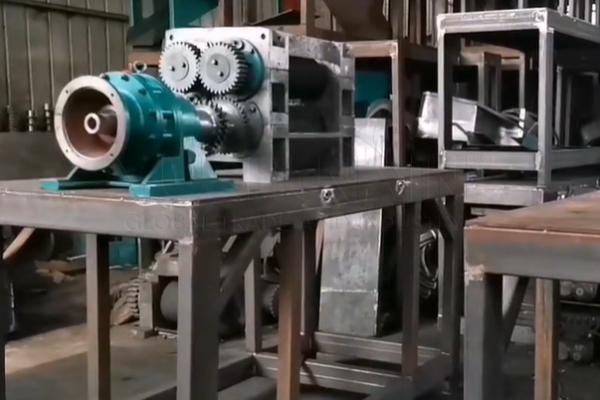

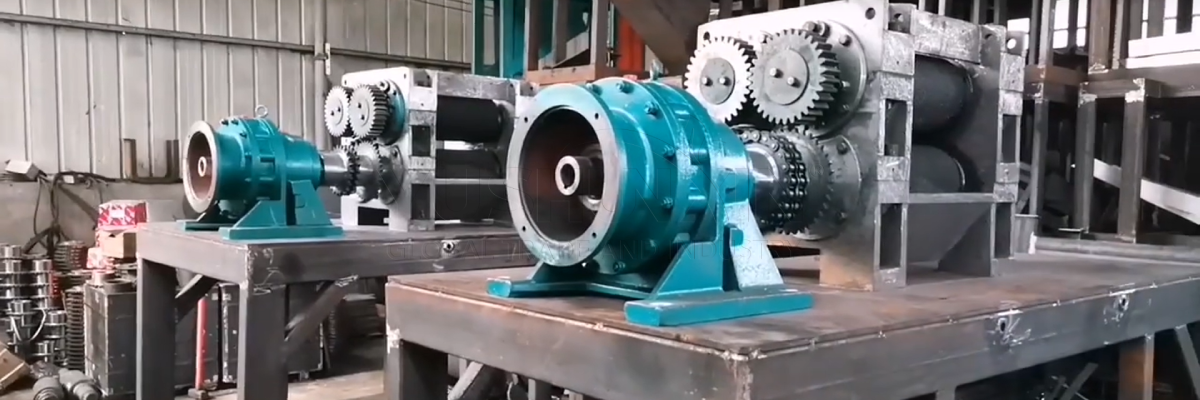

The composition of the equipment of the two-layer roller granulator SXDG-2.5T.

System of feed: provides uniform supply of material to the granulation zone.

Two -layer roller:

- The first layer of rollers: used for primary pressing of materials.

- The second layer of rollers: provides a higher pressing effort, guaranteeing the density and strength of the granules.

Transmission system: includes the engine and chain gear To ensure the smooth operation of the video.

Unloading system: After the formation of particles, they are unloaded through the outlet for the convenience of collecting and transporting.

The main characteristics.

- Effective molding: The two -layer design of the rollers increases the efficiency of molding and the quality of the granules.

- Homogeneous particles: Precision rollers provide a uniform size and form of particles.

- Simplicity of operation: The equipment has a simple design, convenient in operation and maintenance.

- Energy -saving design: The optimized transmission system reduces energy consumption and increases production efficiency.

- A wide range of application: can work with materials of various types and properties.

A two -layer roller granulator can be used in:

- Chemical industry: Production of particles of catalysts and adsorbents.

- Industrial industry: Suitable for granular production of nitrogen, phosphorus and potassium fertilizers.

- Pharmaceutical industry: Pressure of granules of drugs and drugs of traditional Chinese medicine.

- Food industry: used for the manufacture of seasonings and particles of healthy food.

- Battery production: Granulation of materials for batteries, such as graphite powder. Improve the performance and life of the battery.

- Plastic industry: Suitable for the production of plastic supercontacrates, such as technical carbon. Improve the operational characteristics and stability of the color of plastic products.

Recommendations for buying and maintenance.

- Choose a suitable model: Choose the right one Model of equipment for a two -layer roller granulator in accordance with production needs.

- Equipment material: When choosing equipment, make sure, what details, Contacting with the material, made of wear -resistant and corrosion -resistant materials.

- Regular maintenance: Regularly check and serve the components of transmission and pressing, for the equipment to work efficiently.

- Support for suppliers: Choose supplier, which provides good after -sales maintenance and technical support.

The two-layer roller granulator SXDG-2.5T was the perfect choice for many industries due to its effective and uniformly forming particles. Its design and performance will help you increase production efficiency and product quality, as well as reduce production costs. If you are interested in acquiring or receiving more detailed information about a two -layer roller granulator, Contact us. We will provide professional advice and support taking into account your needs, To help you choose the most suitable equipment solution.